The golf course is under construction and irrigation is about to commence, but who will lay out the irrigation system?

In new construction, and many renovations, the plans are normally unstable with frequent changes made to the golf course design during the construction process. These changes can be a result of clearing and specimen trees, balancing excess cut and fill, adjustment to grading to improve the design or avoiding obstacles such as rock, changes to the grass perimeters by the architect, and others. Sprinklers are like dominoes since they are designed in triangular patterns. When one moves, they all must move.

Who will interpret these changes during the layout process? How will they lay it out and when? These questions must be answered. If not the designer, then maybe someone on the contractor’s crew with limited knowledge in irrigation design or philosophy, or maybe the golf course superintendent if one has been hired. Probably neither. There are many design principles that should be taken into consideration during the layout process that someone unqualified would not understand.

The irrigation designer is definitely the most qualified person to make these changes.

The sprinklers need to be laid out correctly or they will be wrong forever. If not correct, this can result in poor turf conditions, poor playability wasted water, and the power to pump it.

Traditionally, a tape measure method was used for layout for years to make sure the spacing and patterns were correctly maintained. This requires the designer to be on-site in a timely manner multiple times during the construction process to avoid construction delays.

Normally, once the shaping is approved and grassing limits are defined by the architect, irrigation needs to commence as soon as possible as each hole is completed. If the project is near the irrigation designer’s office, then layout visits by the irrigation designer are normally not a problem. However, on projects not so near, this is much more difficult to accomplish and costly, especially in the new post-Covid world.

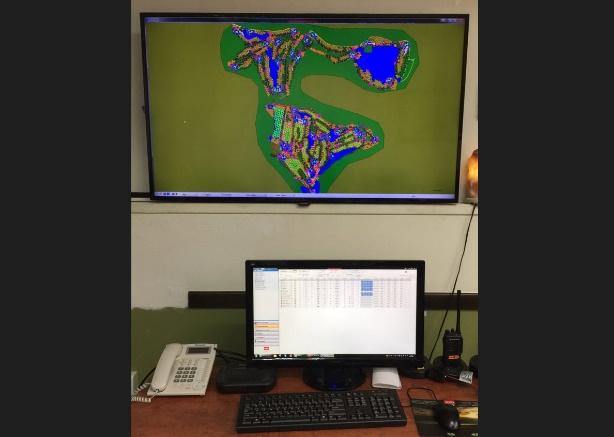

Having designed golf course irrigation systems in over 40 countries, Aqua Turf International understood these challenges of time and travel costs and developed an improved Survey Method Layout process.

Survey Method Sprinkler Layout:

- Provides the best and most efficient sprinkler layout

- Ensures the layout is accomplished in an expeditious manner, no waiting for site visits to be scheduled

- Utilizes personnel and equipment already available on site.

- Reduces the number of site visits and travel costs.

ATI has successfully implemented this process outside the USA for over 10 years in countries such as Bulgaria, Thailand, Vietnam, Greece, Pakistan, China, Turkmenistan, Russia, and others around the world.

How is the Survey Method Layout performed?

Rather than tapes, ATI utilizes survey equipment and technology that is already being used during the construction process. The steps of the process are:

- After shaping and grass lines have been marked and approved by the architect, the Contractor will survey all the “as-constructed” golf features such as the grass perimeters, the perimeter of the greens, tees, bunkers, water features, and cart paths. This AutoCAD file is then provided to ATI either via email or while on-site.

- ATI will then re-layout the sprinkler locations in the computer and return the “As-Staked” drawing to the Contractor. The “As-Staked” drawing then becomes the foundation for the “As-built” drawing. At the same time, ATI also prepares a sprinkler tracking sheet showing the quantity of any sprinklers added or deducted. This will account for any differences between the design and “As-Staked” quantities.

- The Contractor then uses the same survey equipment to lay out the new “As-Staked” design just prior to installation. Site visits at this point are optional. ATI will check the staking and make field adjustments as necessary either during a site visit or via photos and/or “As-Staked” notes using email or video with the on-site coordinator.

- After the staking is finalized, any changes should then be re-surveyed by the contractor and provided back to the irrigation designer. The stakes can remain until installation or be pulled and resurveyed later if they are in the way and installation may not happen soon.

- ATI will update the “As-Staked” drawing to include station numbering and station IDs necessary for modern computer programming. Programming of the computer by ATI or others can then commence. Prompt programming of the computer is critical, especially on decoder systems so as soon as the irrigation is installed on each hole it can then be planted.

Optional Site Visits

Site visits should be scheduled, if possible, to coincide with this process. Ideally, ATI will make an initial visit to review this process with the Contractor and occasional site visits to check the staking and make field adjustments as necessary. Adjustments are typically minimal, leaving more time for the important tasks of installation inspection and plan interpretation. The number of ATI site visits can be tailored to the needs of the project.

There may come a time when only one or two holes are ready to stake, and the time and cost don’t justify a site visit from ATI.

If ATI visits are not made for any reason, the on-site staff can make any minor modifications and review them with ATI via photos in email, phone, or video discussions. The more experienced the on-site supervisor, especially in the Survey Method Sprinkler Layout process, the fewer visits are required, if any.

If the project is on a fast track this method allows the Contractor to continue if needed without a site visit if time is of the essence. Once the site personnel is experienced in the process it is very easily implemented.

Why does Survey Method Sprinkler Layout Provide the Best Results?

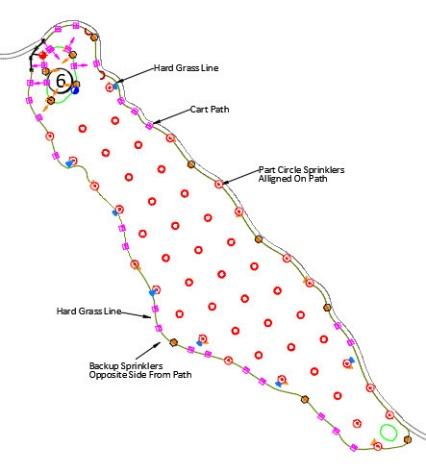

Survey Method Sprinkler Layout allows ATI to totally redesign the system using the computer just as the original design was created. Most modern-day golf courses are designed with part circle sprinklers along hardline grass edges on both sides of a hole to reduce the irrigated area and save water.

Using the computer, the triangular grid can be rotated to best align along the longest straight grass line. Several variations can be tried until the best sprinkler layout is found. We typically use the cart path side as the most critical side to align to since it has the highest visibility and traffic.

In this manner, fewer sprinklers are required since most sprinklers are aligned on the straightest grass line requiring fewer backup part circle sprinklers to fill in behind.

Using a tape method starting at the green is virtually impossible to accomplish to as high a degree.

Survey Method Sprinkler Layout produces the best possible sprinkler layout because:

- The view from above in AutoCAD takes the guesswork out of staking.

- We can set the baseline and rotate the triangular grid as needed to fit any hardline edges reducing the number of backup sprinklers. This results in fewer sprinklers installed but with the best placement AND saves money.

- Eliminates the inherent distortion and human error of dragging tapes or ropes across fairways and over mounds, sometimes in high wind.

- Often the construction is incomplete when the layout is needed such as drainage so portions of the hole cannot be accessed with tapes.

- The process is not weather dependent.

- The contractor immediately has an accurate as-staked plan to work from and the grass lines supplied by the architect in the field are archived for future grassing.

- A solid foundation is already prepared for the as-built drawing and computer programming.

- Decoder systems require the computer to be programmed before irrigation and planting can commence. Since the as-built is created as we go the computer can be programmed immediately.

- Flags that get knocked out during drainage installation or from shaping can easily be surveyed back in their designed location. When using tapes, the stakes must be maintained and can be in the way of soil preparation and drainage.

- More flexible regarding the schedule than using tapes during site visits since holes can be done individually. Also, if design changes are made after staking, a new layout can be easily redone by repeating this process for just that hole.

- No need to stake holes well in advance of installation since the process can be done remotely if needed.

- The time during site visits can be better spent on inspection and plan interpretation than pulling tapes!

Don’t take our word for it. Below are a couple of recent references from projects performed during Covid with no delays or problems.

David Mathews – Construction Manager, Desert Landscape, Rumanza Golf Course, Faldo Golf Design – Multan, Pakistan

“Due to the COVID-19 pandemic, we were faced with no consultant visits for the duration of the Rumanza construction. Once we had an entire golf hole with all shaping and feature works ready for approval by Faldo Golf Design we then moved on to the next activities of drainage, irrigation, cart paths, etc. After approval had been given to proceed to irrigation the required features and grass lines were surveyed to an ‘as built’ for Aqua Turf to provide a new sprinkler layout to the as-constructed course. After we staked and approved that revised sprinkler layout from ATI, we then approved them to add the lateral pipe network. We also received from ATI the updated data on sprinkler quantity, nozzle changes, and all data for flow zones and cable routes at the same time.

Although visits by ATI during the project would have been great, we managed to find a workable system with ATI to achieve the goals of Rumanza. The course is well on its way to being grown in with a professional irrigation system designed by Jim and the Aqua Turf team. As long as you have good site construction and survey teams this Survey Method layout system has proved to be a very good way to proceed.”

Martin Moore – Flagstick GCCM President

“Due to the severe travel restrictions caused by the Covid-19 pandemic which prohibited actual irrigation designer site visits, Flagstick worked very closely with Jim Schumacher and the ATI team to perform all technical irrigation services “virtually”, including staking, programming & consulting on 3 projects in Vietnam during 2020 – 2021: Novaworld (36 Holes), Serena Valley and Binh Tien Golf & Beach Resort. Through the exchange of accurate detailed survey data and other modern forms of advanced communication, this process proved both effective and efficient. I have no doubt that the final completed irrigation system meets the high-quality design and operation requirements that both ATI and Flagstick projects are accustomed to. I would not hesitate to “virtually” perform these same irrigation services again if global conditions required”.

In our new Covid world minimizing visits can be very helpful. We may be moving past Covid, but limiting time, travel, and costs while doing a better job is just good business sense. Consider Survey Method Sprinkler Layout by ATI for your next project.